History of Cominco

The story of Cominco and the Rossland Mines began approximately 150 million years ago. Red-hot magma surged from the deep underground, causing mineral rich aqueous solutions to well up into cracks, cooling and crystallizing, becoming veins of high-grade metal ores - gold, silver, and copper.

In 1864, the riches hidden under the earth’s surface in the East Kootenay were discovered. Hundreds of prospectors came, hoping to strike gold However, the fever soon ended and the area quieted down. It wasn’t until July 1890 when Joe Moris, a French Canadian prospector, and his partner, Joe Bourgeois, staked the first successful mining claim in Rossland. As news spread of the discovery at Red Mountain, the area became saturated with hopeful prospectors, leading to the establishment of a vibrant, wide-open tent town, now the City of Rossland.

In less than two years after Bourgeois and Moris discovered the Rossland Mines, an impressive amount of rich, copper-gold ore was produced. The ore was taken for treatment by wagon or sleigh, six miles to Trail Creek Landing on the Columbia River. Here river steamers took the ore south, where it was finally treated in American smelters.

The laborious and costly routine of getting the Rossland ore to market came to the attention of a flamboyant, young entrepreneur, Frederick Augustus Heinze. Heinze believed that building a smelter at Trail Creek Landing so ores could be treated locally would prove to be convenient and lucrative. In 1896, construction was complete on a gold and copper smelter.

At the same time, Heinze decided that the only efficient way to transport the ore from mine to smelter was by rail so he secured three provincial charters to build railways. It wasn’t long until the railway giant Canadian Pacific Railway came bargaining for Heinze’s railways rights. In 1897, Sir William Van Horne, president of CPR, appointed a competent young metallurgical engineer, Walter Hull Aldridge, to act as a negotiator.

The discussions between Heinze and Aldridge stalled when Heinze wanted more than Aldridge thought the railways rights and smelter were worth. Heinze suggested playing a hand of poker to settle the difference between Heinze’s asking price and CPR’s bid, which was around $300,000. Instead they dragged J.S.C. Fraser, manager of the Rossland Bank of Montreal, out of bed in the middle of the night to act as an arbitrator.

The next day, CPR acquired Heinze’s holdings, which included the smelter, his railway charters and all of his rail holdings for approximately $800,000. Aldridge stayed on to expand and improve the smelter, becoming Manager of Western Operations by March 1, 1898 when the smelter was renamed The Canadian Smelting Works.

Aldridge recognized the value in the smelter owning its mines, so a vital move was merging the mining and smelting interests. In 1905, Aldridge initiated the consolidation of the Rossland Mines, the St. Eugene Mine and the smelter. Agreement was reached with the War Eagle, Center Star, and St. Eugene Mine owners and CPR gained a controlling interest in them for $825,000. The Le Roi Mine was not included in the consolidation at this time.

In 1906, the new company was named The Consolidated Mining and Smelting Company of Canada Limited (CM&S). The relationship between CM&S and CPR continued to be mutually beneficial. CPR received increasing amounts of business from the mines, plus a share in CM&S profits. CM&S took advantage of CPR as a powerful financial backer and set out to expand smelter production, securing more sources of ore for the Trail Operations.

CM&S continued to expand its exploration program recognizing that future fortunes of the company depended upon significant ore reserves.

As CM&S made the transition into the 60s, the company experienced large-scale expansion and diversification. In 1966, the company dropped the name of the Consolidated Mining & Smelting Company of Canada Limited and became Cominco Ltd.

As a result of Cominco’s diversification program, the company created and acquired an impressive group of sivsidiary and affiliated companies throughout the world. These included Pine Point Mines Ltd., Western Canada Steel Ltd., West Kootenay Power & Light Company Ltd., Rycon Mines Ltd., and the Mitsubishi Cominco Smelting Company Ltd., just to name a few.

In 1970, the company moved its executive and sales offices from Montreal to Vancouver, which became Cominco’s official head office location in 1972.

There has been a smelter in Trail, BC for over 100 years. It has evolved from crude to sophisticated modern technology and provides British Columbia with one of its main economic engines. The 1991 opening of the Red Dog Mine in Alaska has ensured the smelter’s success into the future. Red Dog is the world’s largest sinz mine and is the major supplier of Trail Metallurgical Operations’ high-quality concentrate. It is projected to maintain its supply for at least 40 years.

The Merge: Cominco-Teck

The beginning of the 21st Century ushered in the merger of Cominco Ltd. and Teck Corporation, the two oldest continuously operating mining company in Canada.

Innovation and the development of sustainable business initiatives that focus on environmental stewardship go hand-in-hand at Trail Operations. Canada’s first lead-aced battery recycling program was developed here in the 1980s. Today, battery waste is received from all over North America and the recycled lead from those vehicle batteries composes up to 20% of the total refined lead produced at Trail.

Trail Operations Site Map

More recently, Trail Operations implemented a new recycling process to reclaim metals contained in “urban ore.” This process offers a solution to the critical societal and environmental problem of the increasing volume of electronic waste, such as computers and televisions, discarded into landfills. Metals from the electronic and lead contained in the glass monitors are recovered for reuse in new products through our lead smelter - a modern, world-class process equipped with efficient recovery capabilities and stringent environmental controls. The recycling of end-of-life electronics began in 2006 and Trail Operations currently recycles e-waste from BC, Alberta, and Saskatchewan.

Resource diversification followed the 2001 merger; and, in 2008, the company was renamed Teck Resources Limited to reflect this.

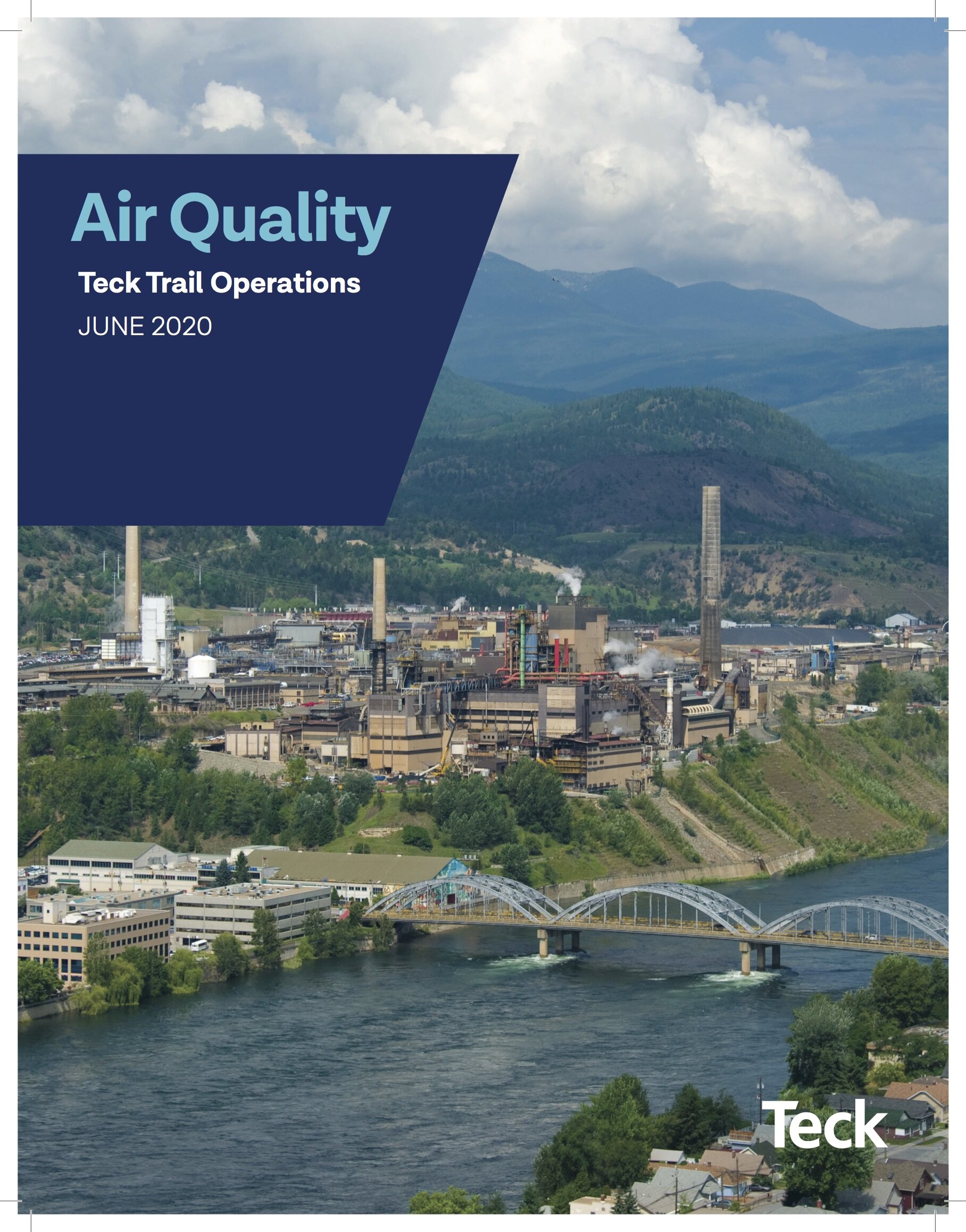

Click through the below brochures for PDFs on

various topics from Teck!

Continue Indoor Tour:

Contribute your own memories/experiences of CM&S/Cominco/Teck:

The form below will email us your message. If you prefer to speak to us directly or have other questions or comments about this page, please call (250) 362-7722 or email the archives directly at archives@rosslandmuseum.ca